Stock Code

301678

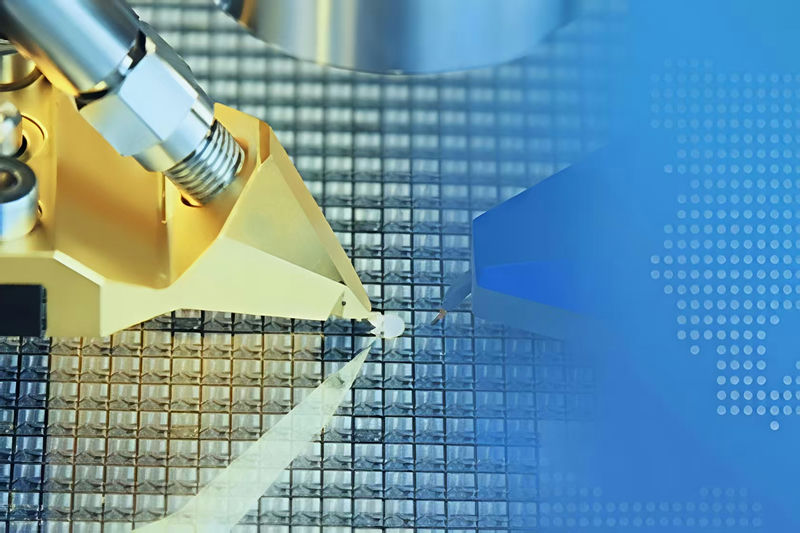

HENGHUI provides customers with one-stop packaging solutions, covering the entire process from wafer BG and sawing, packaging, FT testing, to IoT card personalization. The company has its own high-speed tin-plating line, and the packaging workshop is certified under the IATF16949 Quality Management System, with a monthly capacity of 35 million units. Main product series include DFN, QFN, and MP2, with a focus on etched leadframe packaging, committed to providing customers with high-reliability products and first-class services.

Wafer Diameter (BG, Sawing, Die Bonding): : 6 inches, 8 inches, 12 inches

Minimum BG Thickness: 100μm

Minimum Dicing Saw Slot Width (Blade): 60μm

Process: LOW - K/Non - LOW - K

Minimum Dicing Saw Slot Width (Laser): :60μm

Minimum Chip Size (Die): 0.15*0.15mm

Minimum Bonding Pad Pitch (BPP, Gold Wire): 45μm

Minimum Bonding Pad Open (BPO, Gold Wire): 40*40μm²

Minimum Bonding Pad Pitch (BPP, Alloy Wire): 50μm

Minimum Bonding Pad Open (BPO, Gold Wire): 43*43μm

Minimum Bonding Pad Pitch (BPP, Gold Wire, Alloy Wire, Gold Wire): 55μm

Minimum Bonding Pad Size (BPO, Gold Wire, Alloy Wire, Gold Wire): 45*45μm

Wire Diameter: 15-50μm

Wire Length: 0.2-4mm

Al thickness on Pad (Gold Wire): Al-Cu structure ≥0.6μm

Al thickness on Pad (Alloy Wire): Al-Cu/Al-Si-Cu structure ≥0.8μm

Al thickness on Pad (Gold Wire, Alloy Wire, Gold Wire): Al-Cu/Al-Si-Cu structure ≥1.2μm

Previous: QFN Module

Next: New MP2 Packaging